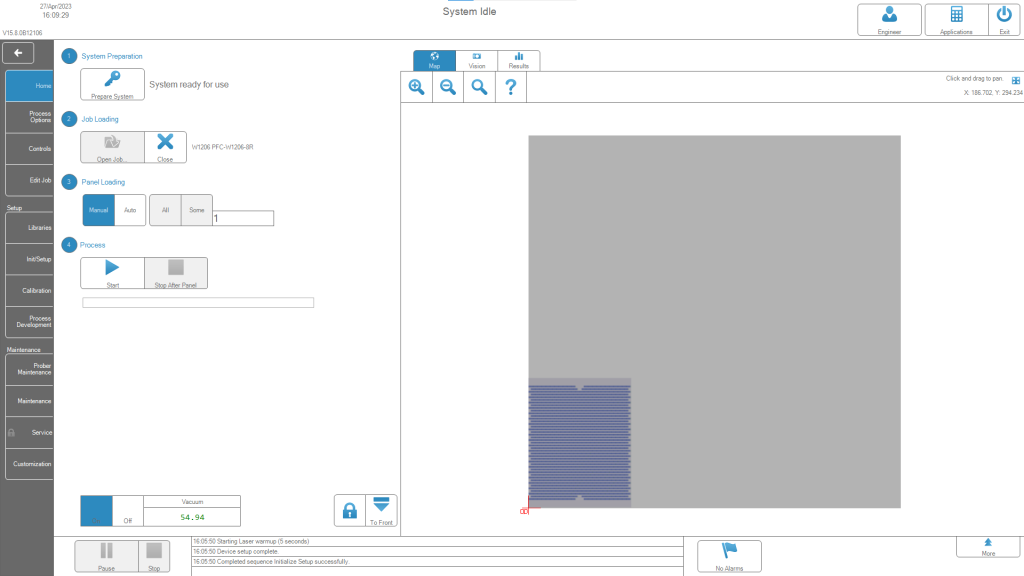

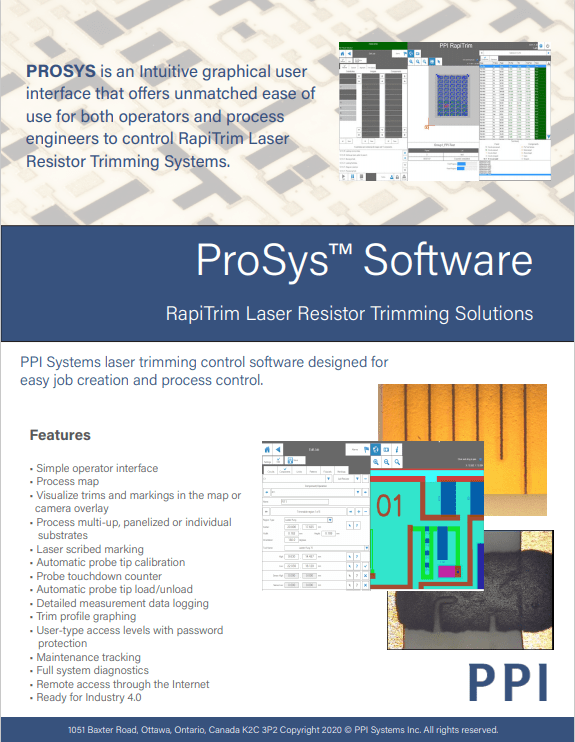

PROSYS LASER RESISTOR TRIMMING SOFTWARE

Resistor Trimming Software

An intuitive graphical user interface that offers unmatched ease of use for both operators and process engineers. All machine setup and calibration controls, job and process settings, vision and process map, status and diagnostic information – accessible with a single click or tap.

Features

- Simple operator interface – load panels and just press Start.

- Process map – visualize all job features in map or camera overlays. Clearly see at a glance what and where the process is, in real time.

- Fully automatic run-time calibration activates when it needs to, ensuring process stability and accuracy.

- Real-time system monitoring for process integrity

- Touchscreen support for all Operator interaction

- Automated file conversion and job creation without operator intervention

- Compatible with industry standard file formats

- File conversion automation with network interface and barcode reading allows unattended job creation

- Automatic multi step and multi pass processing with performance optimization

- User type access levels with password protection for visibility and access to configuration, set-up and operating screens

- Maintenance Tracker keeps log of all system maintenance and history, and provides prompts at maintenance intervals

- Full system diagnostics and data logging for enhanced product support and predictive maintenance

- Remote access through the internet allows factory support without the cost of a service visit

- Multi-language selectable

- Windows 10 64-bit architecture

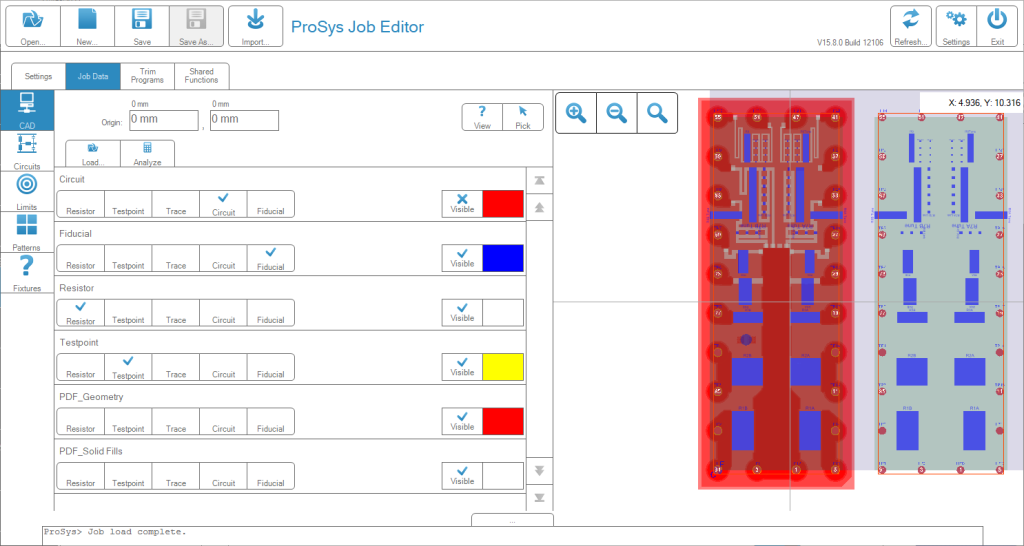

Job Creation

Job creation is through an interactive graphical map of components, circuit features, alignment targets, and trims. Extensive DXF and IPC-D-356 file import support automates and speeds job creation.

- Resistor location, orientation, values, and limits are automatically defined.

- Probe test points can be automatically defined from DXF metalization information.

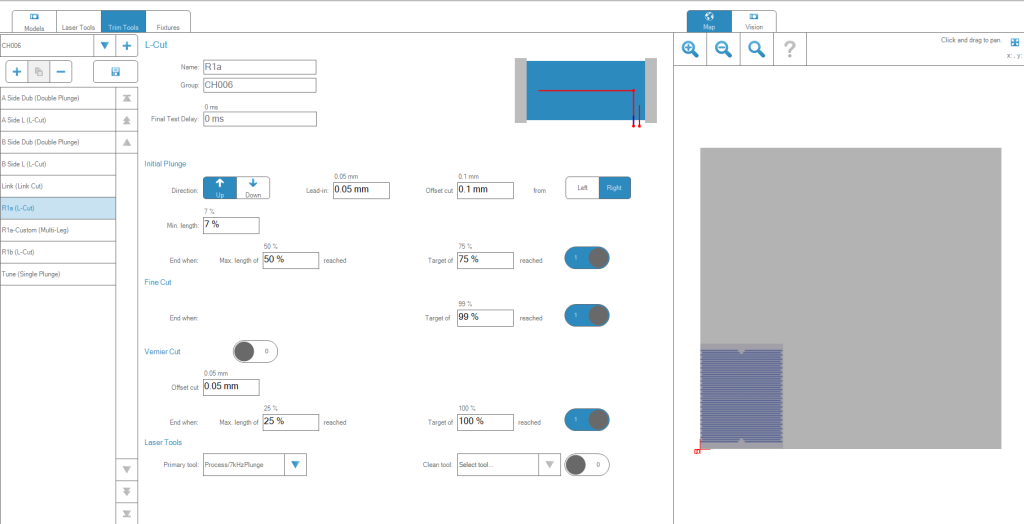

Process Control

Interactive graphical process library with no programming required. Trim and measurement tools can be shared by resistors of different sizes and orientations, minimizing setup steps.

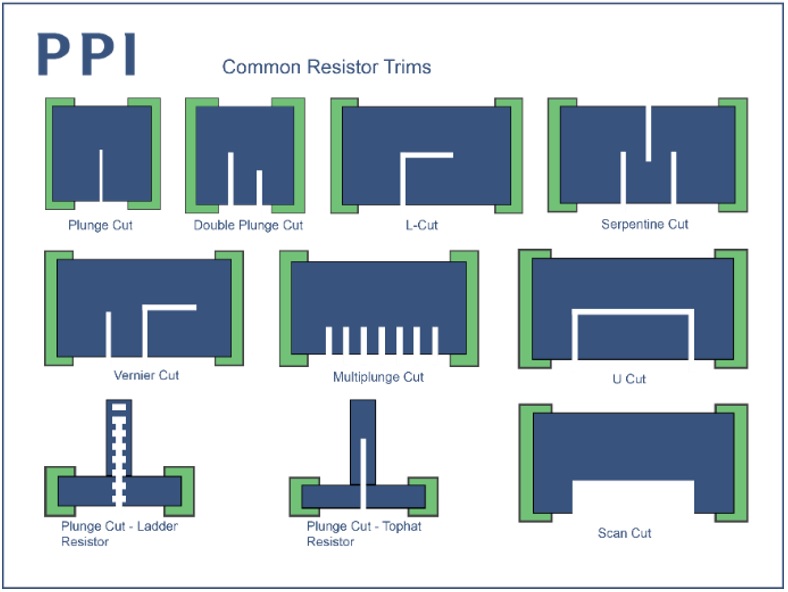

- Complete flexibility with single-plunge, double-plunge, L, vernier, scan, serpentine and custom multi-leg cut trims with settable cut length limits

- Independent control of laser pulse energy, repetition rate and bite size.

Trim and Test Results

Easily view detailed results for each component with data logged by substrate serial number providing off-line historical data review and tracking.

- Single button click performs manual retests on an individual resistor.

- Real-time results update during operation.

- Statistical data report generation.

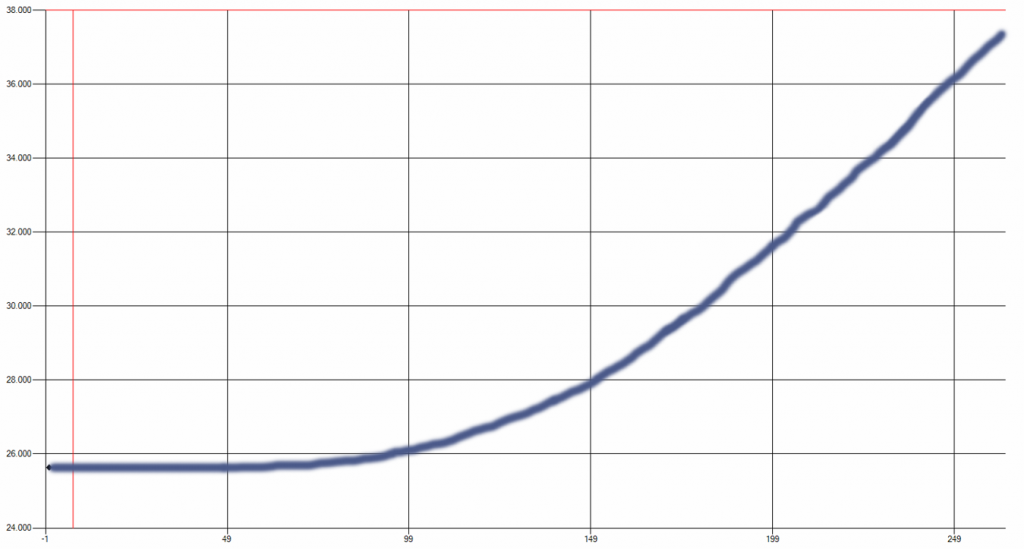

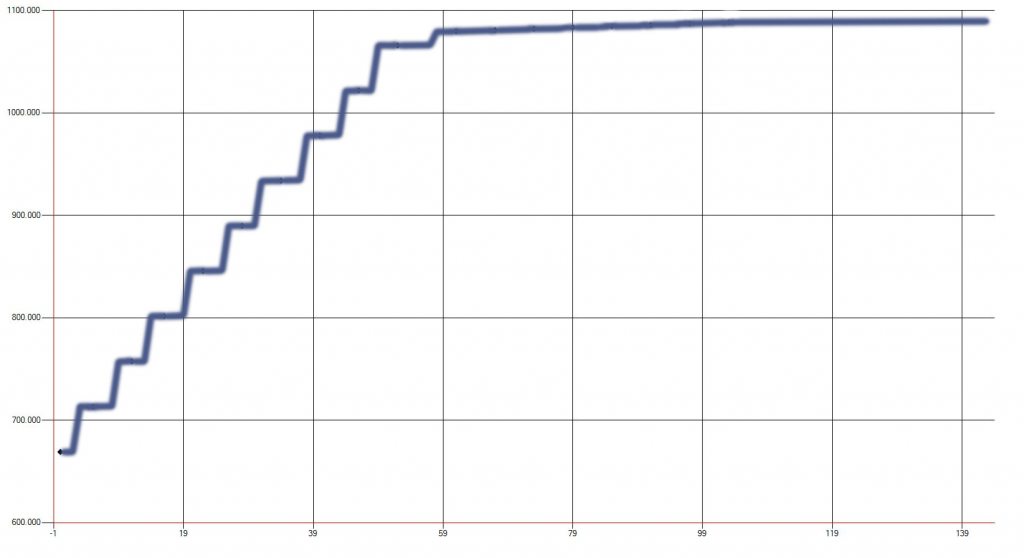

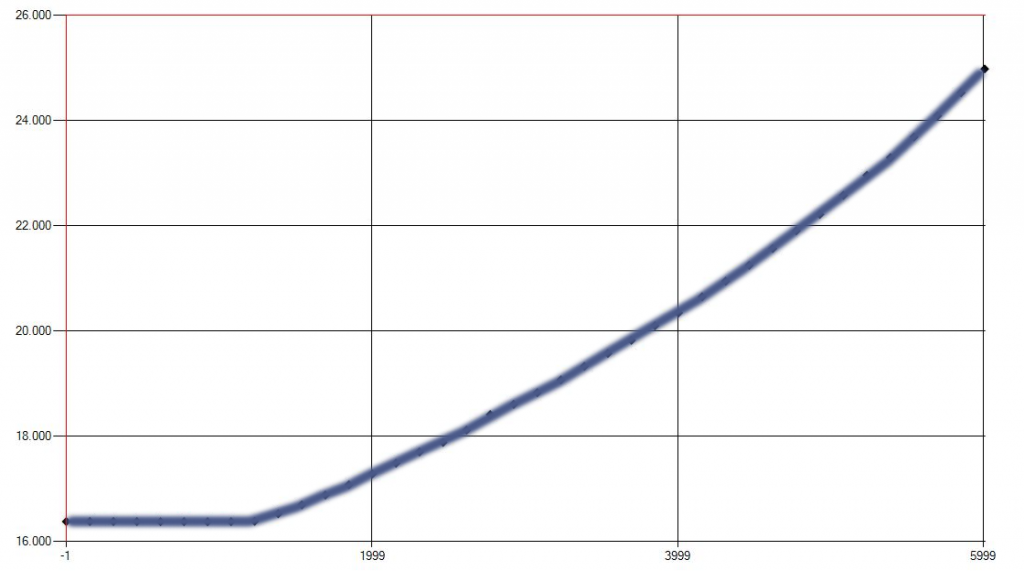

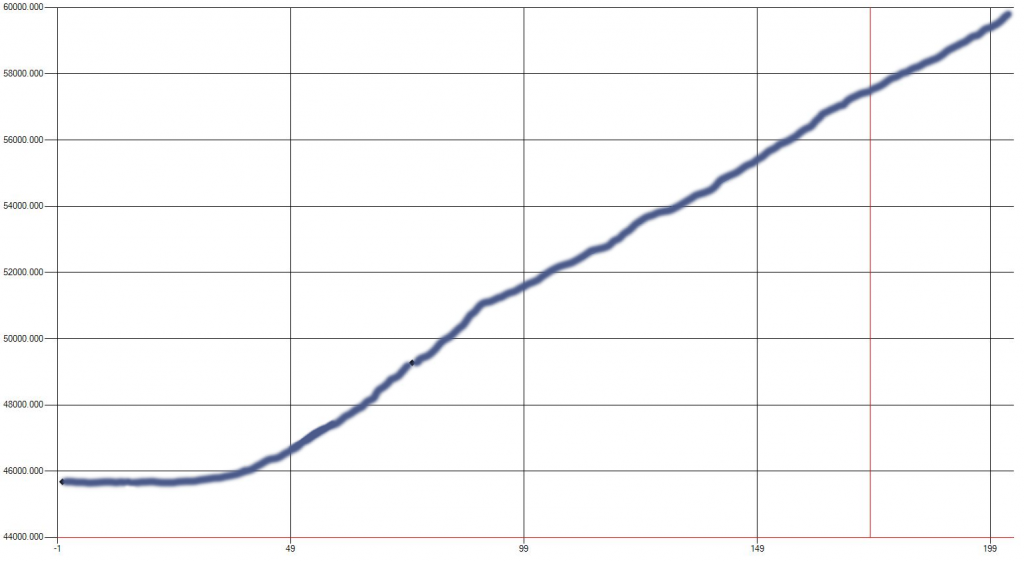

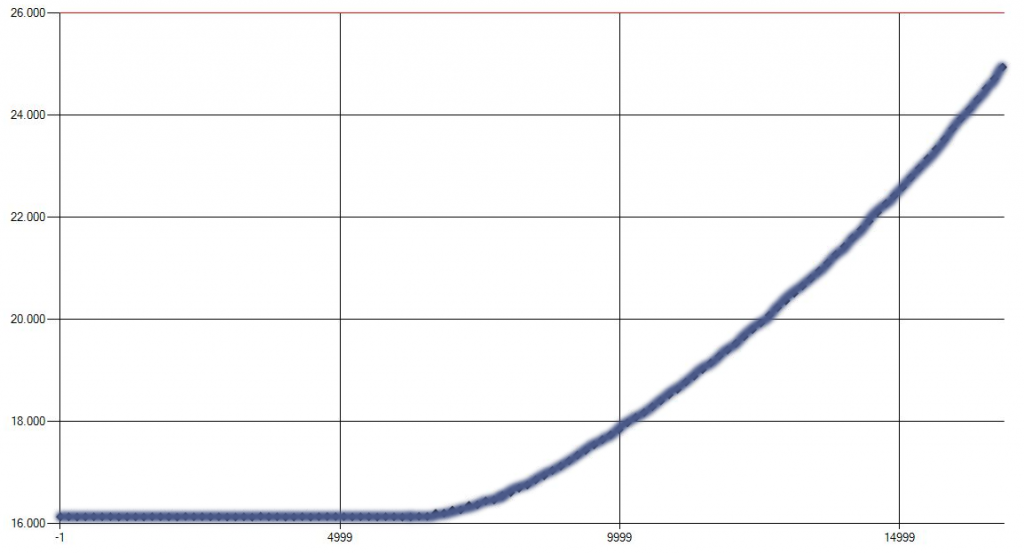

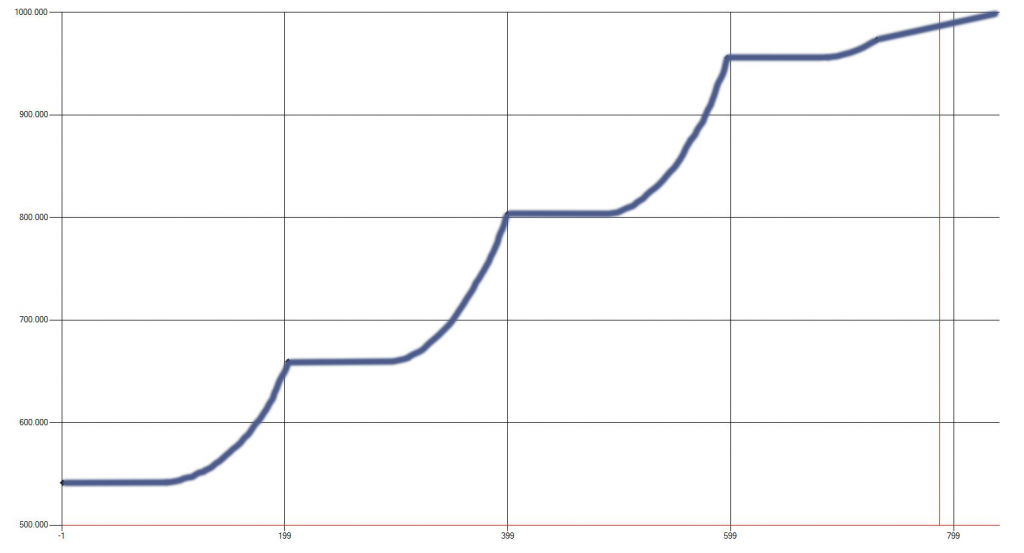

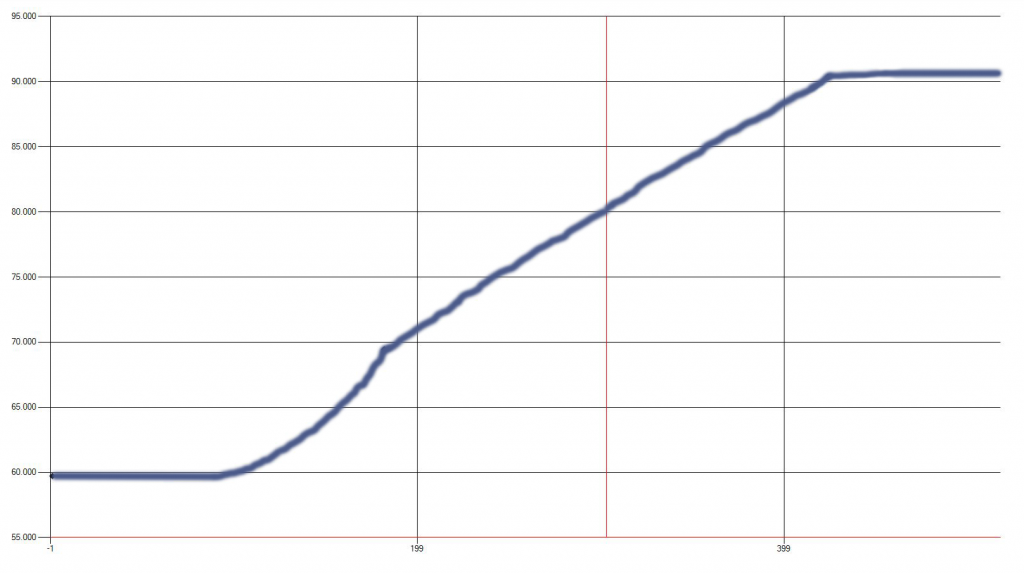

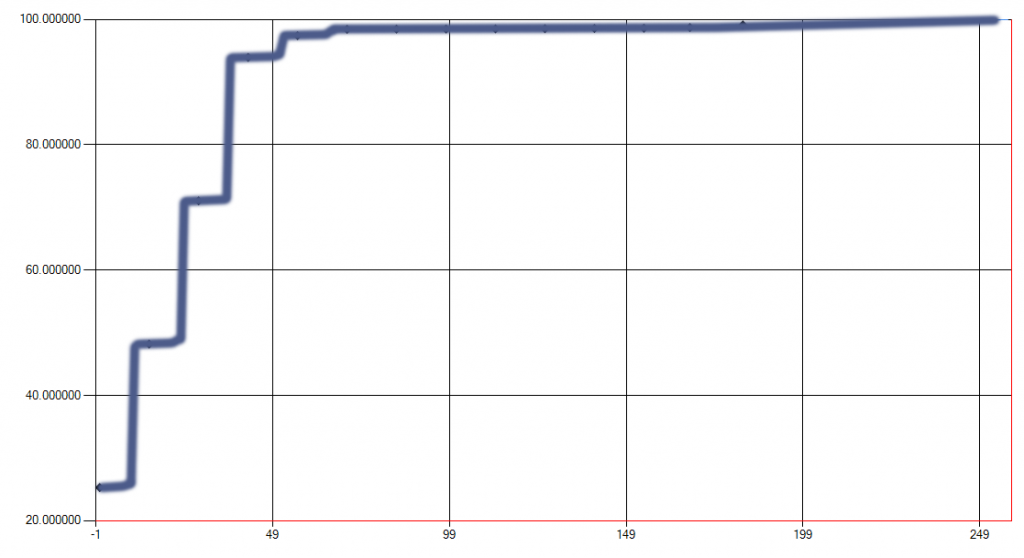

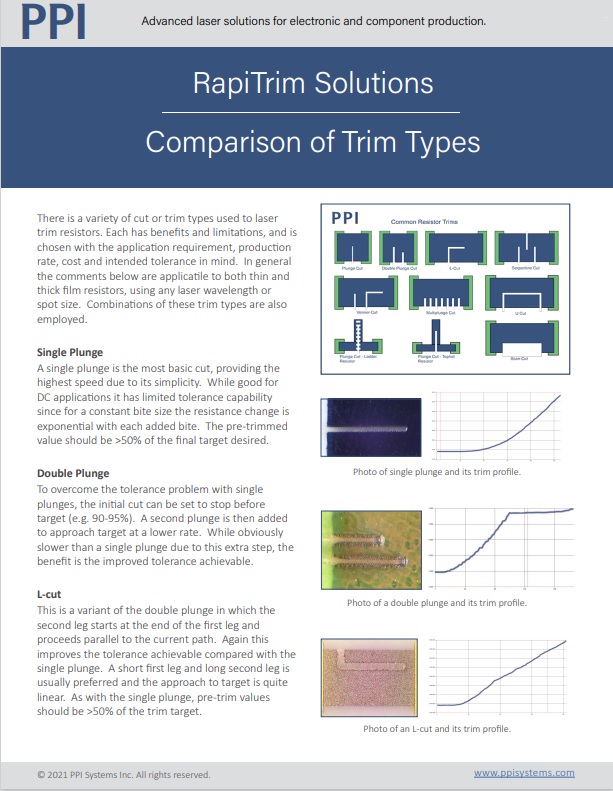

Trim Profile Examples

Resources