OTTAWA APPLICATION LAB

Where Efficient and Intelligent Solutions Come to Life in Collaboration with Our Customers

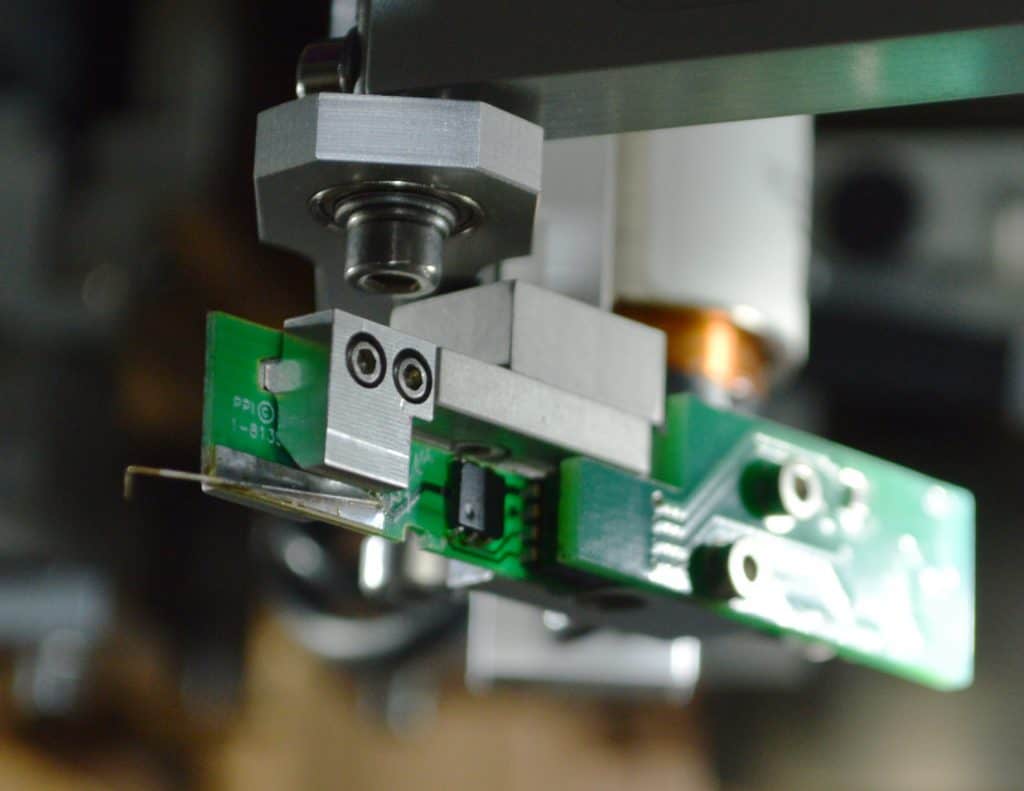

PPI’s main 3500 sq. ft. application lab offers an outstanding array of services for both laser drilling and resistor trimming customers. Our highly trained technical team have a deep understanding of laser processing with over 100 years of combined experience providing solutions to customers.

Benefits

- We support customers and partners with technical application services and product development as well as tailor made training in our globally linked application lab.

PPI Systems application engineers have extensive experience in the laser processing industry with many unique laser drilling and trimming applications.

We extend our system offering with forward-looking products, applications and concepts based on industry trends and customer specifications.

The lab allows the creation of turn-key solutions specifically designed for unique user applications.

Laser Processing Application Specialists

PPI Systems application engineers are experts in handling resistor trimming and via drilling samples in our laser processing systems. Their tasks includes carrying out feasibility studies on customer materials and supporting our sales teams in demonstrations and application tests. Specialists work tirelessly to find the optimal laser parameters for a wide variety of materials, developing new applications and processing samples of materials to ensure PPI processing systems provide optimal results.

Determination of Process Parameters

To assist customers in determining the optimal trimming and drilling parameters for production quality and speed for each sample (thick film, thin film, PCB …), tests are performed using RapiTrim and ProVia systems. These parameters are provided to PPI customers with complete reports generated by the ProSys control software. PPI has an extensive database of applications, saving system users laborious preliminary testing.

Development of Trimming and Drilling Applications

PPI application engineers are constantly exploring available laser cut and drill parameters to find solutions for unique customer requirements. The process must be sufficiently robust before PPI will recommend it for a customer’s production environment.

Post-Production Support

Once a system has been received by a customer the application laboratory allows PPI R&D and engineering staff to use the wide array of application lab systems to work in parallel with customer systems. This allows them to assist process engineers, operators and maintenance personnel with job creation, process control and maintenance procedures.

After the first month or two PPI has found that the number of customer questions rapidly decreases as customer knowledge and confidence grows. The success of the PPI design and operational philosophy for turn-key systems needs to be experienced to be fully appreciated. This is setting new standards in how systems are designed, built and supported.